Logistics

Mediterraneo’s logistical capabilities are a cornerstone of our trading and industrial success. We maintain strategic partnerships with trusted ship owners, securing prime berthing spots in local and international ports. For smaller shipments, our container loading operations ensure efficient and seamless transit

To guarantee the quality and integrity of our goods, we engage independent third-party inspectors to monitor loading, discharge, and maintenance throughout the transportation process. Their meticulous reports provide assurance of our merchandise’s quality.

On the domestic front, our extensive fleet comprises 55 trucks, 30 cars, seven service vans, and two buses, supported by a network of storage facilities and distribution centers. This infrastructure enables us to transport goods nationwide, maintaining exceptional quality standards while minimizing costs. Our clients benefit from competitive pricing for premium products.

With decades of experience, our supply chain is expertly equipped to handle the most complex logistical demands, delivering tailored solutions that exceed our clients’ expectations.

Industries

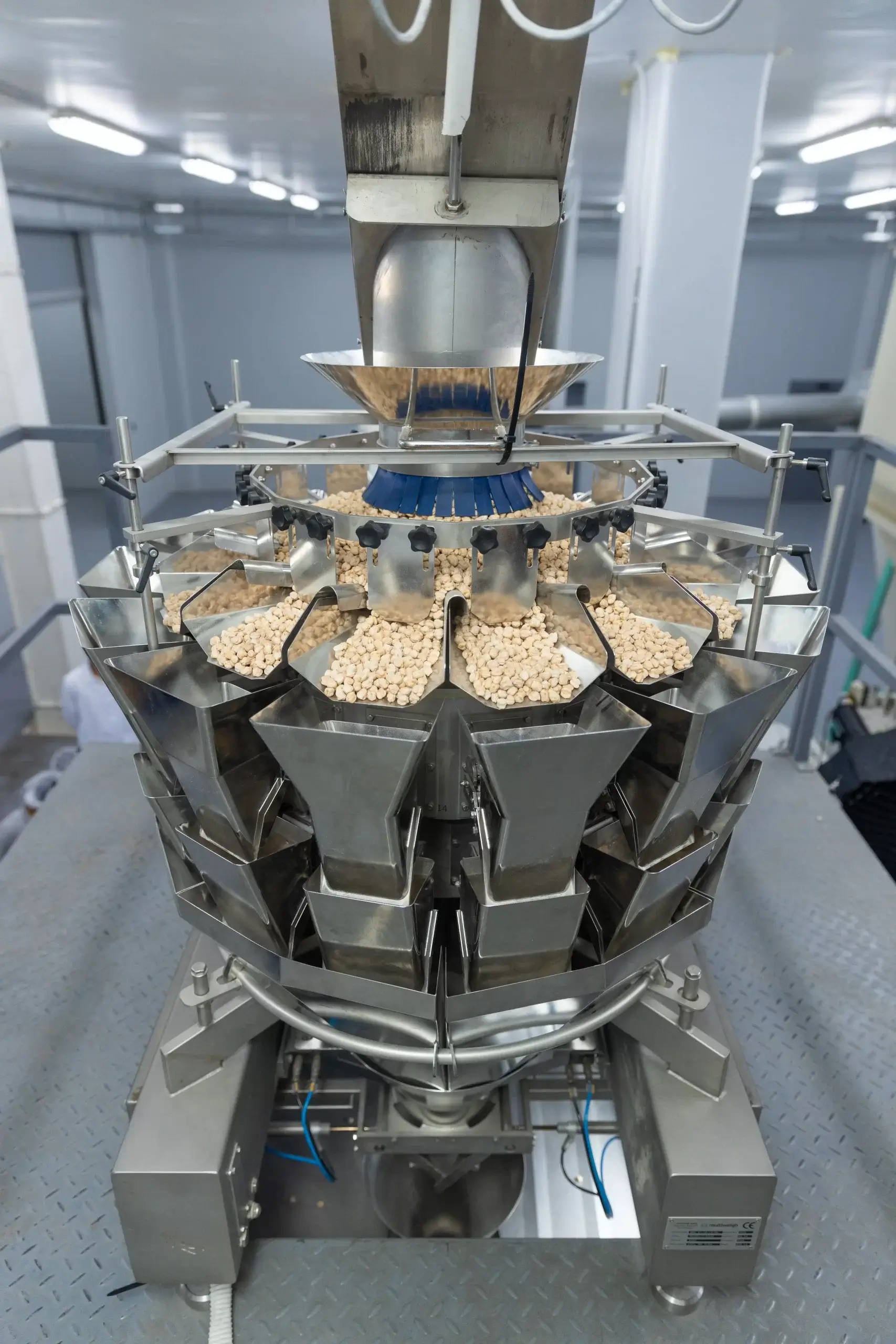

Mediterraneo Industries produces high quality products at our three facilities located in Fayoum, Damietta and Gamasa. We use the latest machinery to sort, clean, split and package the commodities we import for our clients while enforcing world-standard hygiene procedures.

All three of our facilities are certified ISO 22000 and our Fayoum and Damietta factories are whitelisted by the NSFA. Mediterraneo Industries ensures that goods are well preserved against insect infestation and fungus development with its wireless temperature- controlled silos and chiller cooling silos to keep our raw material in the best condition. Our products remain free from any pesticides and preservatives making them safe for human consumption and ensuring no harm is done to the environment.

We have installed solar panels on all three factories, to minimize our use of environmentally endangering energy sources. Additionally, we have several electric forklifts and elevators. We are constantly looking for ways to optimize our factories while decreasing our carbon footprint. Mediterraneo has pledged to reduce our carbon footprint by 500 tons by 2025.

Factories

Factories

Fayoum Factory

In 2006, Mediterraneo Industries inaugurated its state of the art facility in Fayoum which was upgraded in 2013. Our Fayoum factory is spread across 5,600m2 and has around 11 silos with 7,000 tons of storage space and packages products for our wholesale business.

Equipped with state-of-the-art machinery, like a double functioning line for cleaning and splitting from Turkey, a cleaning and packaging line with technology from Switzerland’s Buhler and a cleaning line from Denmark’s Cimbria.

The facility can process 100,000 tons of fava beans per year, it is considered the biggest plant of its kind in the country. The plant has three lines of production, silo storage and refrigerated storage.

We are proud to say that the Fayoum facility is whitelisted by the National Food Security Authority (NSFA) and is ISO 22000 certified.

Damietta Factory

Our Damietta facility became fully established in 2016 with a total space area of 15,000m2 and deals with sorting and cleaning of pulses, and is our wholesale packaging zone. This factory is whitelisted by the National Food Security Authority (NSFA) and is ISO 22000 certified.

We are a leader in the production of quality lentils in the MENA region. Damietta processes around 150,000 tons of pulses yearly, approximately a quarter of which is lentils.

In Damietta, Mediterraneo has six refrigerated silos, commonly referred to as reefers that can store up to 12,000 tons, ensuring that stock won’t be ruined by the summer heat. The plant has five lines of production and 17 silos with a total capacity storage of up to 25,000 tons.

Our Damietta factory is close to the Damietta port meaning the commodities make a short journey from the port to the factory where they have very limited contact with the outside environment.

Gamasa Factory

Our Gamasa facility is mainly used for packaging and storing. It is the biggest in terms of size, spanning across 20,000m2.

In Gamasa, our consumer facing brands undergo lab trails and a last round of sorting. We manually sort through our range of pulses and manual asses and expel bad beans from the good beans.

Our products are packaged in their branded packets using state-of-the-art Rovema machinery from Germany. Our factory staff has perfected the art of packaging in this factory. They efficiently manage the machines and the storage space available.

At Gamasa, we have 25,000 tons of temperature-controlled space which we use for storage.